Unveiling the “Rice Mill Machine Price in India”: A Comprehensive Guide

India, a nation deeply rooted in agriculture, relies heavily on its robust rice milling industry. For anyone looking to venture into this profitable sector, or simply seeking to upgrade existing operations, understanding the “Rice Mill Machine Price In India” is a crucial first step. This isn’t a fixed figure; rather, it’s a spectrum of costs influenced by technology, capacity, automation, and the specific components required. At Ricetec Machinery, we aim to provide clarity, helping you navigate the options and make the best investment for your rice milling aspirations.

The Diverse Landscape of Rice Mill Machines

The term “rice mill machine” can refer to a single piece of equipment or an entire integrated plant. The price fluctuates wildly depending on what exactly you’re looking for:

1. Mini Rice Mills (Home & Small Farm Use)

These compact machines are designed for small-scale processing, often used by individual farmers for their own consumption or local sales. They are characterized by:

- Low Capacity: Typically processing 100-500 kg of paddy per hour.

- Basic Functionality: Often combine hulling and polishing in a single unit.

- Lower Power Requirement: Usually 1 HP to 3 HP.

Price Range: A mini rice mill with a 3 HP motor can start from as low as INR 20,000 and go up to INR 50,000 to INR 1,00,000 for more robust models with integrated features like a de-stoner or grader.

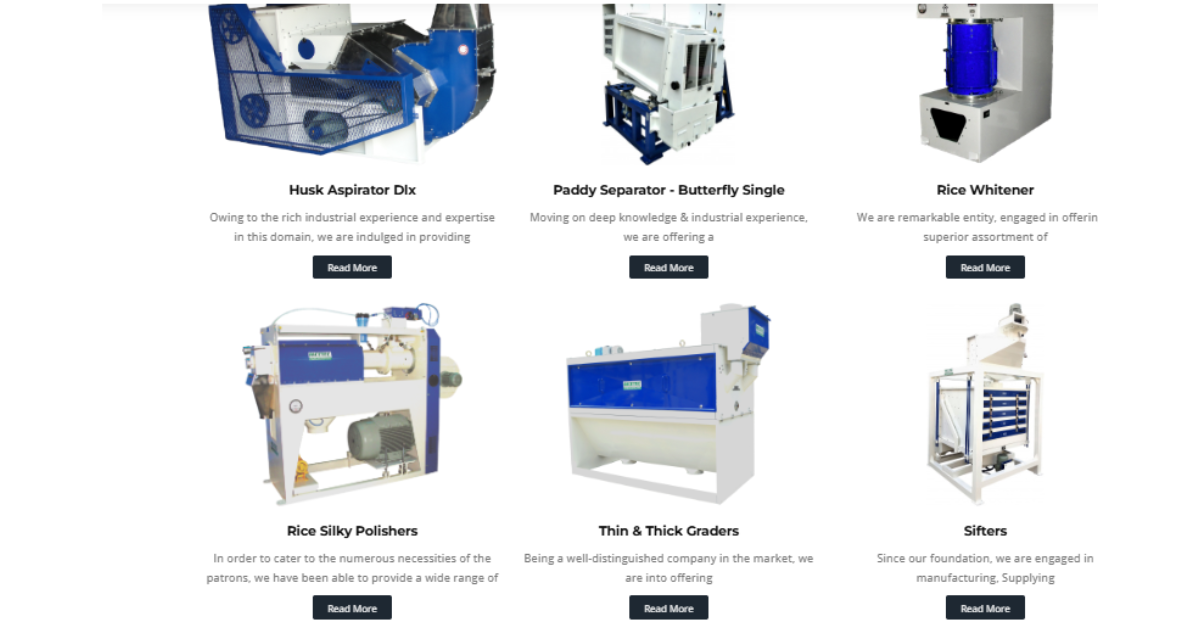

2. Commercial Rice Mill Machines (Individual Components)

For medium to large-scale operations, a complete rice mill is often built by assembling various specialized machines. The price of each component contributes to the overall cost:

- Paddy Cleaners: Essential for removing impurities. Prices can range from INR 2 lakhs to INR 6 lakhs, depending on capacity and design.

- De-stoners: Crucial for removing stones and heavy impurities from paddy. These can cost anywhere from INR 1.5 lakhs to INR 3 lakhs. Ricetec Machinery offers conventional and vibro de-stoners in this range.

- Paddy Hullers/Shellers: To remove the husk. Vibro shellers and pneumatic rubber shellers from Ricetec Machinery are efficient options. Their prices can range from INR 3 lakhs to INR 8 lakhs or more, based on capacity.

- Paddy Separators: For separating unhusked paddy from husked rice. Ricetec Machinery’s Butterfly Paddy Separators (Single Body and Double Body) can range from INR 2.7 lakhs to INR 5.2 lakhs.

- Rice Whiteners/Polishers: To remove the bran layer and polish the rice. Ricetec Machinery’s Silky Rice Polishers are designed for high-quality output and can cost from INR 3 lakhs to INR 5 lakhs.

- Rice Graders (Length Graders, Thickness Graders): For sorting rice by size and shape, crucial for uniform quality. Prices can vary from INR 2.5 lakhs to INR 5 lakhs.

- Color Sorters: These advanced machines use optical technology to sort rice by color, removing discolored grains, broken rice, or foreign materials. They significantly enhance rice quality and command a higher price, often starting from INR 22 lakhs and going up to INR 50 lakhs or more, depending on channels and technology.

- Bucket Elevators, Conveyors, and Blowers: These are auxiliary equipment for material handling within the mill. Their costs vary based on length and capacity.

- Drying Systems: For moisture content control. If parboiling is involved, the entire parboiling plant, including dryers, can cost upwards of INR 1 crore.

3. Automatic/Integrated Rice Mill Plants (Complete Solutions)

These are comprehensive setups that automate most or all stages of rice processing, from cleaning to polishing and sometimes even packaging. They offer higher efficiency, consistent quality, and reduced labor requirements.

- Small Automatic Plants (1-3 tons per hour): These can cost anywhere from INR 8 lakhs to INR 20 lakhs.

- Medium Automatic Plants (4-8 tons per hour): Expect a price range of INR 40 lakhs to INR 80 lakhs.

- Large Automatic Plants (10-100+ tons per hour): These high-capacity, fully automated plants are a significant investment, starting from INR 1.5 crore and potentially reaching INR 15 crore to INR 20 crore or more for very large and sophisticated setups.

Ricetec Machinery offers automatic rice mill machines and complete plants with prices for automatic rice mill machines starting around INR 35 lakhs and going up to INR 45 lakhs or more for larger capacities.

Key Factors Influencing Rice Mill Machine Price in India

Several variables contribute to the final cost of a rice mill machine:

1. Capacity (Tons Per Hour – TPH)

This is arguably the most dominant factor. A higher processing capacity naturally translates to larger, more robust, and more expensive machinery. The difference between a 1 TPH and a 10 TPH mill is substantial.

2. Level of Automation

- Manual/Semi-Automatic: These machines require more human intervention and are generally less expensive. They are suitable for smaller operations or those with budget constraints.

- Fully Automatic: These plants are designed for continuous, high-volume production with minimal manual input. They integrate various machines with control systems, leading to higher initial costs but significant long-term savings in labor and operational efficiency.

3. Technology and Features

Modern rice mill machines incorporate advanced technologies for better output quality and efficiency. Features like:

- Digital Control Panels: For precise operation and monitoring.

- Advanced Sensors: For optimized processing and minimal grain breakage.

- Energy-Efficient Motors: To reduce electricity consumption.

- Dust Collection Systems: For a cleaner working environment and adherence to environmental norms.

- Specialized Components: For specific rice varieties or outputs (e.g., parboiled rice, fortified rice).

The inclusion of such features will increase the machine’s price.

4. Material of Construction and Durability

Machines made from high-quality, durable materials like stainless steel or robust mild steel will have a higher price but offer a longer lifespan and better resistance to wear and tear. Ricetec Machinery emphasizes using superior-grade raw materials to ensure the longevity of our products.

5. Brand Reputation and After-Sales Service

Reputable manufacturers like Ricetec Machinery, known for quality, reliability, and excellent after-sales support, might have higher prices than lesser-known brands. However, investing in a trusted brand often translates to better performance, fewer breakdowns, and readily available spare parts, saving you money and downtime in the long run.

6. Power Requirements

The motor power (HP) and whether the machine runs on single-phase or three-phase electricity will impact the price, as well as the ongoing electricity costs. Higher HP motors generally mean higher initial machine costs.

7. Ancillary Equipment and Installation

The overall cost includes not just the main processing units but also:

- Pre-cleaning and storage solutions

- Conveying systems (elevators, belts)

- Packaging machines

- Electrical wiring and control panels

- Installation and commissioning services

These can add a significant portion to the “machine price.”

Why Ricetec Machinery? Value Beyond Price

At Ricetec Machinery, we understand that the “Rice Mill Machine Price in India” is a critical consideration. However, we encourage our clients to look beyond just the upfront cost and consider the long-term value. Our commitment is to provide:

- High-Quality, Durable Machinery: Manufactured with precision using ISO 9001:2015 certified processes and superior-grade raw materials, ensuring longevity and consistent performance.

- Optimized Performance: Our machines are engineered for efficiency, minimizing grain breakage, maximizing yield, and reducing operational costs.

- Comprehensive Solutions: From individual machines to complete automatic plants, we offer tailored solutions to meet diverse milling needs and budgets.

- Expert Consultation and Support: Our experienced team provides guidance on selecting the right machinery, plant layout, and after-sales service, ensuring smooth operation and maximum profitability.

- Competitive Pricing: While we prioritize quality, we strive to offer competitive prices that reflect the advanced technology and robust construction of our machines.

Investing in a Ricetec machine is an investment in reliability, efficiency, and a profitable future for your rice milling business.

Getting a Precise Quote

Given the numerous variables, providing a single price list for “Rice Mill Machine Price in India” is impractical and misleading. The best way to get an accurate estimate is to:

- Define Your Needs: Determine your desired processing capacity (tons per hour), level of automation, and specific quality requirements for the rice output.

- Identify Key Components: Based on your scale, list out the essential machines you’ll need (cleaner, huller, polisher, color sorter, etc.).

- Contact Reputable Manufacturers: Reach out to companies like Ricetec Machinery with your requirements. We will provide a detailed quote based on your specific needs, including machine specifications, power requirements, and potential installation support.

Conclusion

The “Rice Mill Machine Price in India” is a diverse landscape, ranging from affordable mini mills for individual farmers to multi-crore fully automated industrial plants. The cost is a direct reflection of capacity, automation, technological sophistication, and the quality of components. By understanding these influencing factors and partnering with a trusted manufacturer like Ricetec Machinery, you can make an informed decision that ensures long-term profitability and success in India’s dynamic rice milling sector. We are here to guide you through every step, ensuring your investment yields the best possible returns.

Frequently Asked Questions (FAQ)

Q1: What is the typical price range for a mini rice mill machine in India?

A1: A mini rice mill machine in India, suitable for home or small farm use, typically costs between INR 20,000 to INR 1,00,000, depending on the motor power (e.g., 3HP), features, and brand.

Q2: How much does an automatic rice mill machine cost in India?

A2: The price of an automatic rice mill machine varies significantly with capacity. A small automatic plant (1-3 tons/hour) might cost INR 8 lakhs to INR 20 lakhs. Medium plants (4-8 tons/hour) can be INR 40 lakhs to INR 80 lakhs. Large, fully automated plants (10+ tons/hour) can range from INR 1.5 crore to INR 20 crore or more. Ricetec Machinery offers automatic rice mill machines starting around INR 35 lakhs.

Q3: What is the most expensive machine in a complete rice mill plant?

A3: Generally, the Color Sorter machine is often the most expensive individual component in a modern rice mill, with prices starting from INR 22 lakhs and going significantly higher for advanced multi-channel models. Other major cost drivers are the overall capacity of the plant and the level of automation.

Q4: Does the brand of the machine affect its price?

A4: Yes, the brand significantly affects the price. Reputable manufacturers known for quality, durability, advanced technology, and reliable after-sales service, like Ricetec Machinery, tend to have higher prices than unbranded or lesser-known manufacturers. However, this often translates to better performance, longer lifespan, and fewer operational issues.

Q5: Can I buy individual rice mill machines instead of a complete plant?

A5: Yes, you can purchase individual rice mill machines such as paddy cleaners, de-stoners, hullers, polishers, and graders separately. This approach is common for upgrading existing mills or for smaller operations that want to build a customized setup. Ricetec Machinery offers a wide range of individual components.

Q6: What factors besides the machine price contribute to the overall cost of setting up a rice mill?

A6: Beyond the machine price, other significant costs include land acquisition, civil construction (building), utilities (electricity connection, water), installation and commissioning charges, initial raw material procurement, labor wages, and various government licenses and permits.